CUSTOM ROAD / TT CYCLING SHOES

MIK.FIT 360

Mik.Fit 360

-

The same angles on you Mik.Fit custom cycling orthotics are incorporated directly into the design of each shoe's base so no additional insole is required. Not only does this ensure maximum connection of each foot against the pedal but it also reduces the shoe's stack height and overall weight.

-

Anything and everything is possible with 3D printing. 3D modelling and printing is more than just about producing beautiful objects. It's about using the latest technologies to create the most aerodynamic and advanced shoe possible with the lightest and strongest materials available.

These shoes are made using the same 3D printing technologies and fabrication principles as Formula One components.

-

The carbon-fibre used in all Mik.Fit custom cycling shoes is sourced specifically to ensure that only the lightest and strongest materials are used in each shoe's fabrication.

The low-cut bathtub base design hugs each foot's profile without coming into contact with the bony areas of the foot (particularly around the navicular bone on the inside of the foot).

The Mik.Fit 360 R1 & TT shoes have an entirely rigid base to ensure maximum power transfer with an upper that it more forgiving for riding longer distances than those required on the track.

-

These shoes have evolved enormously since the original TT shoe's inception.

Proceeding wind-tunnel testing has shown us that laces not only cut the air on the shoe's upper to make them more aerodynamic but the athletes have greater control over each shoe's retention tightness.

The sleek, seamless upper design results in the most comfortable and aerodynamic design.

-

Each shoe's weight is dependent on the foot it's designed to fit. A 50kg cyclist with a size EU 42 will have a different carbon-fibre "recipe" to a 70kg rider of the same size.

Whilst it's impossible to be exact for custom shoes, a typical Mik.Fit custom road shoe for a size EU 43 weights under 170g. This is possible due to the Formula One grade materials that ensure each shoe is both the strongest and lightest possible.

-

Synthetic materials have been the more desired material choice for cyclists for many years due to its weather-resistant and non-stretch nature. This typically ensures the cycling shoe's maintain their shape and form for longer.

Mik.Fit has specially sourced this synthetic material to allow a single, seamless piece that can be draped over the entire shoe. This creates the most conforming, comfortable and aerodynamic fit.

-

This is the easy part. It's your shoe so the shoe will be designed to work with whatever base you prefer or require.

-

With 3D printing everything and anything is possible. Every pair of shoes are made with the lowest stack height possible.

Fully Customised. 3D Printed Design. Foot Orthotic-Integrated. Aerodynamically Tested. Ultra Light-weight. Game-Changing.

Foot Orthotic Intregrated.

The Key to the Shoe’s Success

This is more than just another custom cycling shoe and it’s also far more than its ultra-advanced 3D printed design. It’s your shoe around your most biomechanically efficient foot position. A position completely unique to each foot’s biomechanical needs that it connects the ground with the “power joint” faster so you don’t have to “find it” during each pedal stroke. 20 years of clinical experience formed the biomechanical principles of these cycling insoles, but it took 12 years of working with the world’s best cyclists to develop and fine-tune its recipe for their success.

Your Mik.Fit customised cycling foot insoles are the first and most important ingredient for the shoe’s success. The same angles and the same arch profile are incorporated directly into each shoe's design so no additional insole is required within the shoes. Not only does this ensure maximum connection of each foot against the pedal but it also reduces the shoe's stack height and overall weight.

3D Printed.

Innovation Requires Prescision

The 3D modelling and printing process allows Mik.Fit custom cycling shoes to be built in the same way and with the same materials as custom made Formula One components. It ensures the carbon-fibre at it’s thinnest of 0.8mm and it’s thickest of 2mm in each shoe’s design, has absolutely consistent resin:carbon-fibre ratio throughout to produce the lightest yet strongest products physically possible, whilst also creating something aesthetically beautiful to we`ar. Not only do these shoes suit the demands of the highest tourque-producing cyclists in the world, they can also be proud wearing it.

This is not a direct 3D-printed shoe. 3D printing has evolved enormously but tireless testing during the initial prototyping/development phase identified that this is method wouldn’t fulfill Mik.Fit’s requirements for an Olympic gold-medal winning shoe. Instead, the 3D printing allows for complete control in the shoe’s aerodynamic and lightweight design, ensuring dimensional accuracy and equal resin:carbon distribution.

Low Stack. Rigid Base.

Literally on top of the pedal

Toe spring in cycling shoes is a feature that many question. For Mik.Fit however, the 15º toe spring in each shoe’s design not only helps to activate the power joint (1st MPJ) against the pedal during the down stroke for connectivity, but it subsequently plays a significant role in hiding the 3D printed titanium piece that connects the shoe to the cleats. Regardless of whether you design your shoes with Wahoo Speedplay’s or the three bolt option of Shimano, Look or Time, it can be as low as 2mm. Yes, 2mm.

Just as with the cycling orthotic insoles, they are rock hard to touch but their incredible comfort is due to the fact it’s your foot, in your best position. As long as the pressure is equally distributed, it doesn’t matter whether you’re competing in a Grand Tour or in a Flying 500 on the track, each shoe’s rigidity only adds to the rider’s ability to drive, stabilise and connect to the bike.

Aerodynamic Design.

Aerodynamically Tested

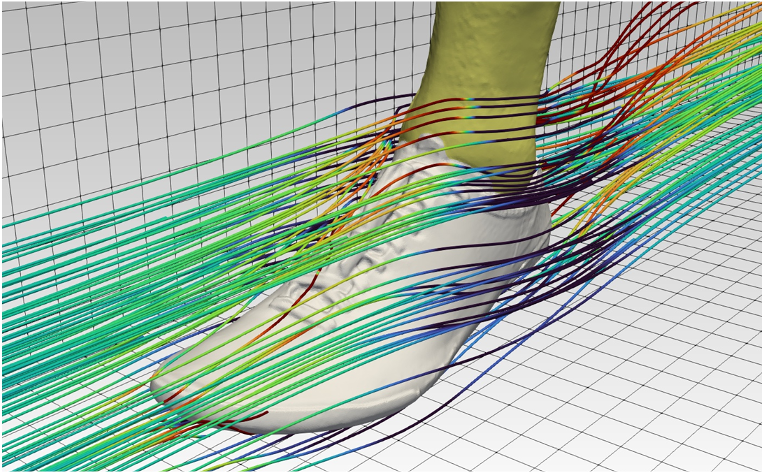

Virtual Windtunnel setup:

Dimensions: 12 x 4 x 4 meters

Speed: 40 km/h

Results (CdA m2): 0.01110

Watts required to overcome aero drag at 50 km/h = 17.9W

WHY HAS THE DESIGN EVOLVED?

There are always two main considerations when contemplating design changes. First and foremost, data doesn’t lie. Wind-tunnel testing with EF Pro Cycling in preparation for the 2022 Tour de France highlighted both the shoe’s advances but also where future versions could be improved.

Right at the top of the list was incorporating laces into the shoe’s design. UCI regulations prevent any shafts/ridges on a shoe (that doesn’t follow the foot’s natural contours) if it changes or enhances the direction of wind flow. Given the full carbon shoe is essentially your foot wrapped in a metal blanket, the wind gets a little lost over the forefoot region, in particular. Laces resolved this issue as they split the air whilst contouring to the natural shape of each foot.

Secondly, but arguably more importantly, it’s the athletes feedback that ensures the product’s longevity. Whilst the full carbon shoe’s glove-like, rigid fit ensured maximum power transfer, it simply wasn’t comfortable enough over longer distances. When Mik.Fit’s earliest riders suggested a more maliable upper, the solution was a synthetic, non-stretch upper attached to a carbon bathtub base. Being able to tighten the shoe’s tension to whatever they felt was ideal not only made them feel more secure, but it made them be able to train and compete wearing their shoes for hours on end.

The rest is history.

Ambassadors

-

Ben Healy.

EF Education-EasyPost | Irish National Road Race Champion

-

Lily Williams.

Paris 2024 Olympic Gold Medal Champion | Women’s Team Pursuit

FAQs:

-

Ben Healy’s (approx 44.5EU) shoes weigh in at 194g finished.

-

Unfortunately no. The moulding process is where everything can be won or lost. If the mould is poorly taken, both the orthotics and the shoes will be a reflection of this and the shoes won’t achieve their objectives. As such, Mick is the only option to take the moulds for the orthotics and the shoes.

-

Some brands choose weight over rigidity and for the others, it’s the opposite. At Mik.Fit, it’s possible to achieve a shoe that’s both lightweight, exceptionally aerodynamic with an entirely rigid bathtub base.

-

Currently no.

-

Whilst they are surprisingly durable, they will suffer when frequently immersed in water. Cyclo-X and MTB riders are the most at risk of this so as always, take them out and pat-dry them but avoid putting them on a heater.

-

No. Come with your current shoes and I can advise you on several options that are the most suitable for you specific width, depth & last before buying them.

The Process.

All Customs Begin as an Orthotic First

If you’ve read this far and serious about Mik.Fit Customs, then you would already understand the importance of getting the Mik.Fit cycling orthotics first. If you’ve skipped ahead, then please read the above information or read more here.

The ideal moment to take the moulds of the whole foot and ankle for the shoes is at the same session once the Mik.Fit orthotics have been fitted. An additonal hour will therefore be added to the fitting (2 hours in total).

Production

The 3D printing process is the slowest part of each shoe’s construction and in many ways it may be considered too slow. However, Mik.Fit approaches each shoe’s construction in the same way as a Formula 1 car component is made via 3D printing and fabrication with carbon-fibre.

From moulds to delivery, our expected delivery time is two months. The good thing is that the client is already using and adapting to the same angles in their Mik.Fit orthotics so the transition into the custom shoes is typically a breaze.

Prices.

-

€695 Bilbao / £645 London

This includes the 45 minute initial apppointment, the moulding process, 1 x pair of custom foot orthotics & the 60 minute fitting appointment.

-

-

-

€180 Bilbao / £180 London

45 minutes.

Not all of our clients needs require our cycling foot orthotic insoles.

If this is the case, this initial appointment will intend to achieve all your needs.

-

€95 Bilbao / £95 London

45 minutes

Follow-up appointment for current / existing Mik.Fit clients to address whatever goals they require.

-

€495 Bilbao / £445 London

-

A foot measurement and three short tests online will be able to determine the time of shoe suitable for your foot type.

All clients will receive a downloadable measuring tool for the online assessment.

"As one of just a few contact points between body and bike, feet remain a shockingly unexploited frontier in the cycling world of marginal gains. Through incredible commitment to detail and individualization, Mick is a pioneer in moving cycling shoes from a small optimization to a massive performance benefit. I think multiple Olympic golds is all you need to know."

Lily Williams.

Paris 2024 Olympic Gold Medal Champion | Women’s Team Pursuit

Contact Us

Reduce pain.

Increase power.

Optimise performance.

Everyone has their own unique reason for coming to Mik.Fit and this same uniqueness applies to each and every one of our custom cycling insoles and cycling shoes.